Tenza Automobile is a joint venture brand established by BYD, a leading Chinese new energy vehicle manufacturer, and Mercedes-Benz, a German automaker. DENZA, a phonetic translation of the Chinese name "Tenza", stands for "Rising Momentum, Electric Future" and aims to create a new luxurious and comprehensive travel experience for users.

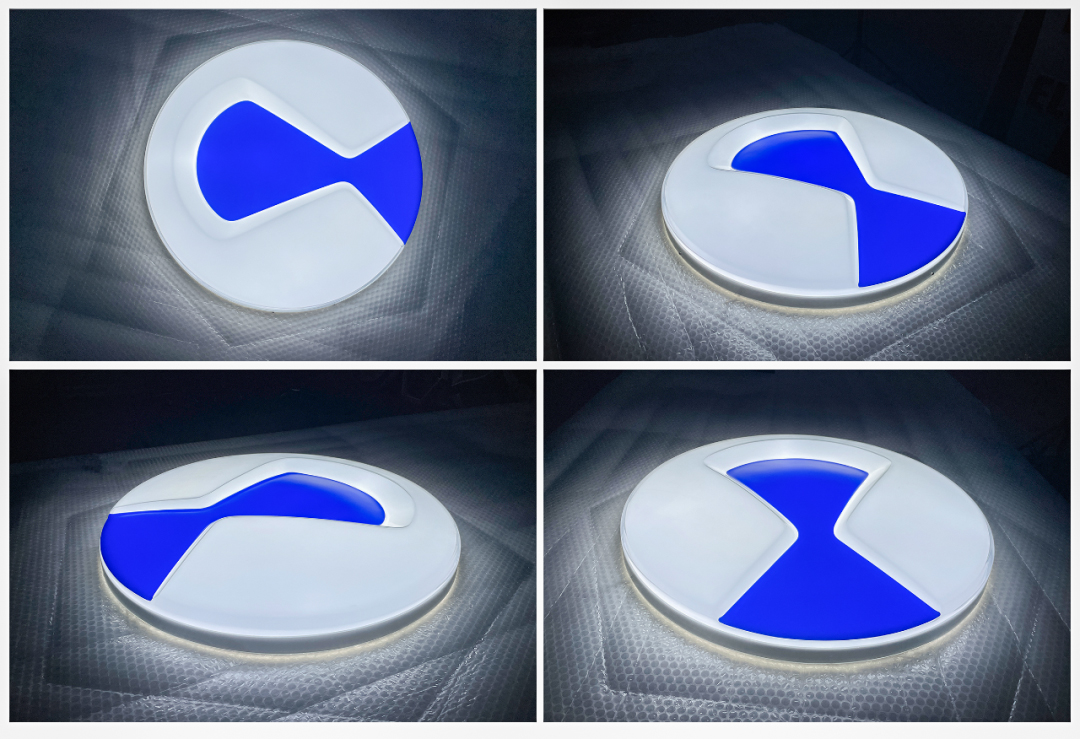

The Tenza New Energy logo features a central water droplet and an enclosing shape as its core brand elements. The blue of the water droplet represents technology and the future, embodying the brand's vision of pursuing a pure and natural environment. The enclosing shape signifies the collaboration between the two joint venture partners, working together to protect nature and the environment, dedicating themselves to the new energy vehicle industry, and fulfilling their environmental responsibilities.

Such a stylish and powerful design requires a beautiful car logo to present it. Goodbong emerged into Tenza's vision, and after going through bidding, sample submissions, and finally winning the bid, both parties began their collaboration.

During the design phase, we received the car logo design draft from our partner and conducted further refinement. Through multiple rounds of communication with the client, we made subtle adjustments to the design to make it more suitable for production, in line with Tenza's brand image and market positioning. At the same time, we also showcased our creativity by injecting new elements into the design, making it even more unique and eye-catching.

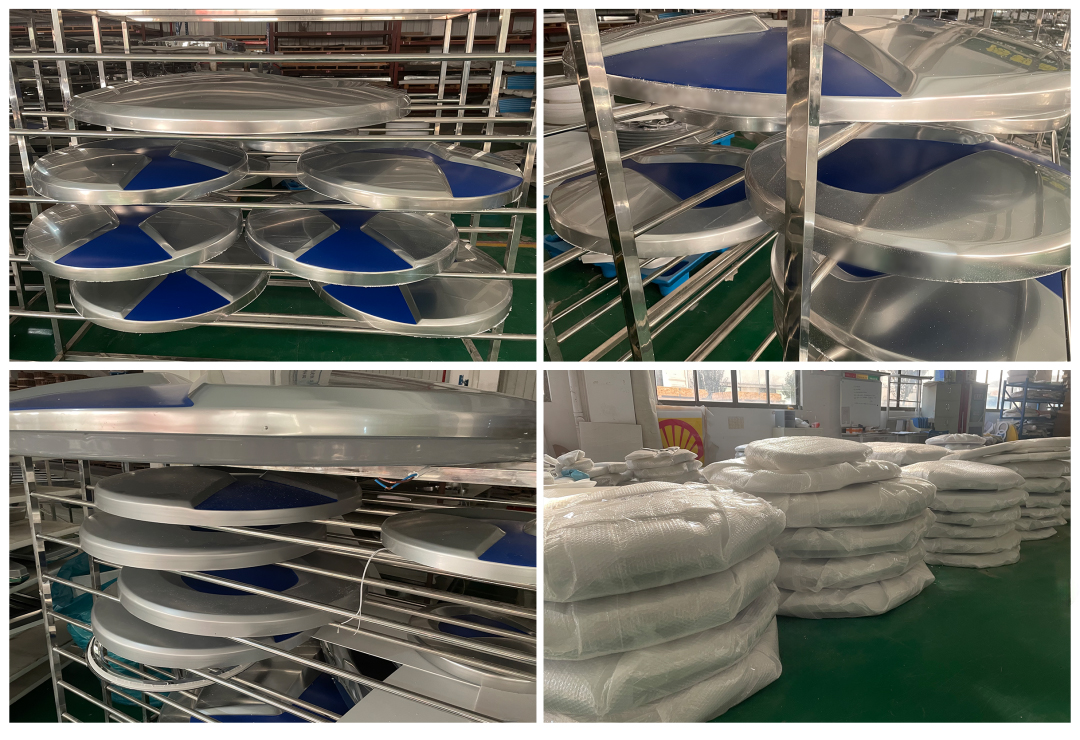

Before commencing production, we engaged in in-depth discussions with the client to clarify the manufacturing process and flow. Given the irregular shape of the Tenza car logo, we opted for the vacuum forming process for its production. For mold selection, we chose aluminum molds based on the client's requirements for precision and quantity. This type of mold offers high precision and long service life, ensuring the quality of the car logo production.

During the production process, we strictly adhered to the established workflow. First, the sheet material was heated and then placed onto the mold for vacuum forming. Once the shaping was complete, the product underwent cutting, grinding, and cleaning. Based on the client's requirements, we applied post-processing techniques such as vacuum coating and film lamination. Without illumination, the electroplated finish reveals a stainless steel effect. When illuminated, it emits a luminous glow. Finally, we applied protective films to the surface, installed lights, and attached the bottom cover, completing the production of a brand-new Tenza car dealership logo. The entire production process was rigorous and meticulous, ensuring precision and durability.

Finally, we conducted quality inspections, packaging, and shipment in wooden crates to ensure the safe delivery to the client. Along with the delivery, we provided installation instructions and relevant technical support to ensure a smooth installation process for the client.